HR Series Desiccant

Air Dryers

3.0 to 50 SCFM

HR Series Heatless Desiccant Air Dryers are the perfect companion to smaller horsepower compressed air systems for providing ultra-dry clean air.

- 8 Models Available to Match Your Application Requirements and Minimize Energy Loss

- Spring Loaded Desiccant Beds Help to Extend the Life of the Desiccant Packed in Each Tower

- Compact Design with Simple, Versatile Mounting and Installation Options

- Fully Re-Pressurizing Design for Steady Outlet Pressure and Flow

- Standard NEMA 4X Electrical Rating

- ISO 8573.1 Class 2 -40°F/C Standard Outlet Dew Point

| Standard Features: |

|---|

|

| Optional Features: | |

|---|---|

|

|

| General Specifications: | ||||||||

|---|---|---|---|---|---|---|---|---|

| HR1 | HR2 | HR3 | HR4 | HR5 | HR6 | HR6.5 | HR7 | |

| INLET Flow: (SCFM @ 100 PSIG) |

3.0 | 6.0 | 9.0 | 12.0 | 16.0 | 25.0 | 35.0 | 50.0 |

| PURGE Flow (SCFM @ 100 PSIG) |

0.8 | 1.6 | 2.4 | 3.2 | 3.4 | 5.4 | 7.8 | 10.8 |

| OUTLET Flow (SCFM @ 100 PSIG) |

2.2 | 4.4 | 6.6 | 8.8 | 12.6 | 19.6 | 27.2 | 39.2 |

| Inlet / Outlet Ports (NPT) |

3/8" | 1/2" | ||||||

| Dimensions: | ||||

|---|---|---|---|---|

| Weight (lbs) |

Height (in) |

Width (in) |

Depth (in) |

|

| HR1 | 8.0 | 13.6 | 7.4 | 5.2 |

| HR2 | 9.0 | 18.2 | ||

| HR3 | 10.0 | 17.3 | ||

| HR4 | 11.0 | 21.1 | ||

| HR5 | 29.0 | 33.0 | 9.5 | 6.5 |

| HR6 | 34.0 | 41.9 | ||

| HR6.5 | 59.0 | 39.3 | 10.0 | 7.0 |

| HR7 | 65.0 | 46.3 | ||

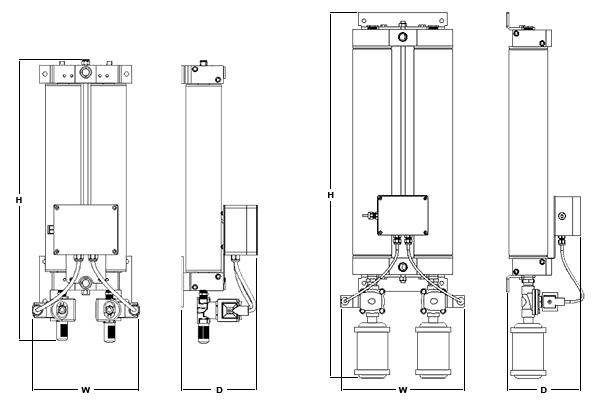

HR1 - HR4 HR5 - HR8

| Multiplier Table (For INLET Pressures other than 100 PSIG): | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Maximum Inlet Flow (-40° F/C PDP) = INLET Flow (above) x INLET Flow Factor (A) @ Actual Pressure (below) Maximum Inlet Flow (-100°F/-73°C PDP) = INLET Flow (above) x INLET Flow Factor (B) @ Actual Pressure (below) Purge Flow = PURGE Flow (above) x PURGE Flow Factor (C) @ Actual Pressure (below) Rated OUTLET Flow = Calculated Maximum Inlet Flow - Calculated Purge Flow |

||||||||||||

| Actual Pressure (PSIG) | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130* | 140* | 150* | 175** |

| INLET Flow Factor (A) | 0.32 | 0.43 | 0.55 | 0.69 | 0.84 | 1.00 | 1.09 | 1.18 | 1.26 | 1.35 | 1.44 | 1.66 |

| INLET Flow Factor (B) | 0.25 | 0.33 | 0.43 | 0.53 | 0.65 | 0.75 | 0.85 | 0.88 | 0.95 | 1.01 | 1.08 | 1.24 |

| PURGE Flow Factor (C) | 0.56 | 0.65 | 0.74 | 0.83 | 0.91 | 1.00 | 1.11 | 1.18 | 1.26 | 1.35 | 1.43 | 1.65 |

*These pressures exceed the Standard input for HR5, HR6, HR6.5, & HR7.

Please Contact Altec AIR for assistance.

**175 PSIG Requires the V1 Option to be selected.

HR Series Drying Process

The HR Series Heatless Regenerative Desiccant Air Dryers employ Pressure Swing Adsorption (PSA) Technology to remove water vapor from ordinary compressed air. The Inlet (lower) Shuttle Valve directs the wet air into the Online Desiccant Tower, where nearly all of the water vapor is removed. The ultra-dry air leaving the Desiccant Tower passes through the Outlet (upper) Shuttle Valve and on to the application. Both Shuttle Valves contain a wafer-like disk, which “shuttles“ back and forth in the valve body based on the pressure differential created by the position of the Two-Way Solenoid Valves. A Purge Orifice in the Outlet Shuttle Disk allows a portion of the dry air leaving the Online Desiccant Tower to be redirected back through the Offline Tower, purging it of its accumulated moisture. The purge stream exits the unit through the open Solenoid Valve directly below the Tower being regenerated. A Solid-State Timer controls the process by opening and closing the Solenoid Valves.

This tool will help you size the perfect HR Series Desiccant Air Dryer for your Compressor Output and Environmental Conditions. Simply enter the data & conditions and you'll be presented with the Part Number for the HR Series Air Dryer that will work optimally for those conditions. We will also provide Part Numbers for the Filter Kits that were created to match that HR Series Air Dryer perfectly.

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.

Please use the latest version of Chrome, Firefox or Safari.

Internet Explorer not currently supported.

Need A Custom Sized Air Dryer?

Contact Altec AIR for assistance selecting the right dryer for your application.

All you need is the required Inlet or Outlet Flow Rate, Operating Pressure, and the required Dew Point.